Key Takeaways:

- The BS EN 124 classification is a set of standards in the UK that defines specifications for gully tops and manhole covers, covering their design, performance requirements, and testing methods.

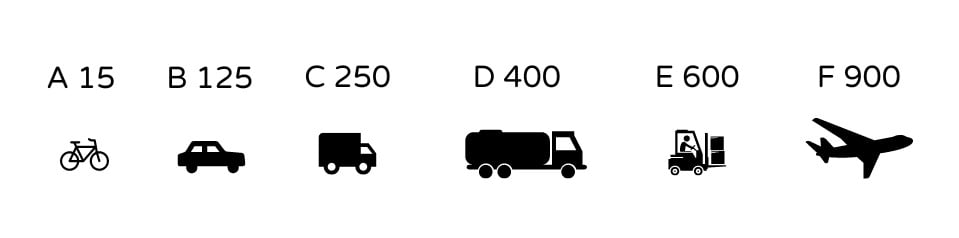

- This classification includes six groups based on environmental usage and several classes based on load-bearing capabilities, ranging from Class A15 to Class F900.

- Materials covered under this standard include cast iron, steel or aluminum alloys, steel-reinforced concrete, composite materials, and plastics like polypropylene, polyethylene, and PVC.

- Manufacturers can use CE marking to demonstrate compliance with European directives and regulations.

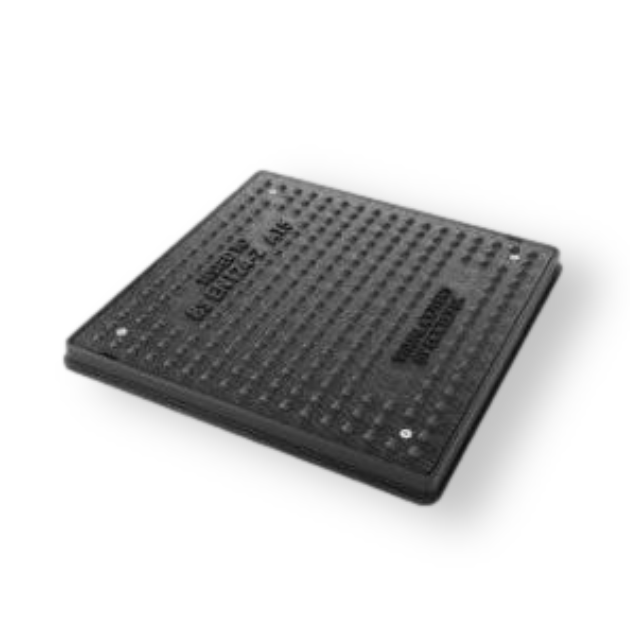

As it's crucial that all types of manhole or access covers are durable, safe, and fit for their intended purpose, in the UK they must adhere to the BS EN 124 classification. Maintained by the British Standards Institution (BSI), this standard ensures high-quality products and safety. Founded in 1901, BSI works towards creating a resilient world by promoting knowledge, innovation, and best practices.

In this article, we’ll guide you through what the BS EN 124 classification entails. It’s not just relevant for manufacturers and safety regulators but also for installers, especially those working in road and civil engineering sectors. We'll outline the different groups and classes for load-bearing, and discuss important considerations when selecting appropriate manhole covers for various applications.

### What the Classification Covers

First published in 1994, the BS EN 124 classification replaced the older BS 497:1976 standard. Originally a European norm, it was adopted by the UK and now covers definitions, classifications, design principles, performance requirements, and testing methods for gully tops and manhole tops made from various materials. After significant revisions in 2015, the standard now includes overarching documentation titled BS EN 124-1:2015, along with five sub-sections focused on specific materials:

- EN 124-2 for cast iron products

- EN 124-3 for steel or aluminum alloy products

- EN 124-4 for steel-reinforced concrete products

- EN 124-5 for composite material products

- EN 124-6 for polypropylene (PP), polyethylene (PE), or plasticized polyvinyl chloride (PVC-U) products

In 2015, the standard was expanded to include detailed guidelines for CE marking, allowing manufacturers to declare compliance with applicable European directives and regulations.

It's worth noting that BS EN 124 does not apply to gratings or covers forming part of prefabricated drainage channels as per EN 1433. It also doesn't apply to surface boxes or floor/roof gullies specified in any part of EN 1253.

### Different Groups and Classes

The BS EN 124 classification includes six groups representing different environments where covers or gratings might be used:

- Group 1: Areas accessible only by pedestrians.

- Group 2: Pedestrian areas and car parks where vehicle access is occasional.

- Group 3: Forecourts, car parks, industrial sites, and areas with slow-moving traffic.

- Group 4: Areas accessible by cars and lorries, such as hard shoulders and carriageways.

- Group 5: High load areas like docks and loading zones.

- Group 6: Areas with very high wheel loads, including aircraft pavements.

Additionally, it includes several classes indicating the static load-bearing capabilities of gully tops, access covers, or manhole covers. These range from Class A15 to Class F900:

- Class A15: Can withstand a 15kN test load.

- Class B125: Can withstand a 25kN test load.

- Class C250: Can withstand a 250kN test load.

- Class D400: Can withstand a 400kN test load.

- Class E600: Can withstand a 600kN test load.

- Class F900: Can withstand a 900kN test load.

These classes can be matched with their respective groups to determine the required load-bearing capability for specific areas, ensuring safety and durability in installations.

For more information on the BS EN 124:2015 classification and other UK engineering standards, visit the [BSI website](https://www.bsigroup.com). Note that full versions of these standards must be purchased to view them as PDFs or printed documents.

### Alternative Classifications

While British Standard classifications are widely recognized, the Fabricated Access Covers Trade Association (FACTA) was established in the early 1990s by manufacturers to create their own grading system for fabricated access covers. Their ratings range from FACTA A (up to 5kN load-bearing) to FACTA F (up to 237kN load-bearing). FACTA aims to offer detailed calculations for varied applications. However, fabricated covers are typically made from steel or aluminum, so they're only suitable for low-traffic areas or zones with 20mph speed limits. FACTA-rated covers should not be used in areas with fast-moving traffic or high load-bearing requirements.

More details about FACTA, including its full specifications, are available on its [website](https://www.facta.org.uk).

### Other Considerations When Choosing a Cover

Besides ensuring compliance with relevant British Standards and selecting covers with adequate load-bearing capacities, you should also consider aesthetics when installing manhole or access covers. Recessed covers can blend well in highly visible and manicured locations like gardens or driveways while still providing sufficient load-bearing capacity for less demanding areas.

If replacing a cover for an inspection chamber, ensure compatibility with the existing frame. If not possible, replace both the cover and frame entirely to maintain structural integrity and safety.

We recommend opting for a higher load-bearing rating if you're unsure, as it's safer to choose a more robust solution than an insufficient one.

### Fully Compliant Covers and Grates

At EasyMerchant, we offer a wide range of manhole covers and gully grates in various sizes and materials suitable for numerous applications. Our products, produced by leading European brands, meet the British Standards outlined here and many carry the Kitemark to denote their high quality and compliance. You can easily find the load capacity of all our access covers on our website, helping you choose the ideal cover or grate for your project needs.

For further advice on access covers or load-bearing issues, or if you have questions about our range of products such as manhole covers, soakaway crates, or underground pipe fittings, feel free to reach out—our expert team is ready to assist.

**Shop Manhole Covers and Frames:**

This article provides a comprehensive overview of the BS EN 124 classification and its importance in ensuring safety and durability for manhole and access covers. Whether you're a manufacturer, installer, or simply looking to upgrade your infrastructure, understanding these standards is essential for success.

A blood Centrifuge is used for the accurate determination of hematocrit values and also for the separation of trace amounts of blood or solution

Blood centrifuge,Blood plasma centrifuge,Blood cell centrifuge

Zenith Lab (Jiangsu) Co.,Ltd , https://www.zenithlabo.com